Business Model

The strengths of the Shimamura Group are product appeal that combines high sensitivity, high quality, and low price, as well as sales power that achieves high profits.

These two strengths are supported by a foundation composed of human resource development, low-cost operation, and original mechanism.

Human resource development

The Shimamura Group believes that the growth of each and every employee is indispensable for the prosperity of a company. In order to grow, employees must acquire knowledge and skills through workplace experience and on-the-job training. Furthermore, through off-the-job training, they are required to lay the foundation for personal growth by learning the necessary basic knowledge, ways of thinking, and ethics required of our employees. Through human resource development, the Shimamura Group supports the self-realization of each employee through their work.

- M-employee system

- More than 80% of Shimamura Group employees are M-employees (regular part-time employees). We established the M-employee system for part-time employees working in stores. This unique system is designed to assist housewives who possess the ability to work but are unable to have a full-time career; specifically, it incorporates a time-shift system to balance efficient working conditions and family life. With M-employees with a high level of ability and in accordance with work-related manuals, we realize store operations by a small group consisting of 1 store manager and 6 to 10 M-employees.

- Store manager promotion system

- The Shimamura Group appoints talented human resources from among M-employees to become store managers. Approximately 70% of our current store managers came from this system. After receiving promotion to the position of store manager, employees can then aspire to even higher positions such as block manager. As such, this system balances ease of work for the employee with personal growth. The goal of being promoted to store manager increases motivation toward work. Not only does this lead to improved abilities of each employee, but it also contributes to the growth of the entire Group.

We have also developed a support structure for employees aiming to become a store manager. Examples of this include the briefing sessions to share the experiences of role model employees and an educational curriculum to train candidates to become a store manager to reduce anxiety about promotion to a store manager. Moreover, we are running an information campaign on career advancement using posters and the in-house newsletter to draw out a desire to aim to become a store manager. - Appropriate workplace assignments

- The Shimamura Group continues to actively hire new university graduates and appoint them to management positions. The personnel matters related to R-employees (full-time employees) are based on job rotation in which employees frequently change posts during their first 10 years with the Group. Afterwards, they are assigned to a department appropriate for their qualities for more than 5 years and trained as specialists. Job rotation enables our employees to acquire a broad perspective, knowledge, and business skills in various departments. As a result, they will grow into talented human resources who always embrace new challenges.

- Fair evaluation of human resources

- The Shimamura Group has established a fair system for evaluating human resources. The goals of the system are to ensure that all employees understand the Group's policy, to ensure that the best possible results are obtained under the orders and instructions of their direct supervisors, and to enable all employees to fully demonstrate their abilities. We also expect our employees to constantly seek a new vision of the distribution industry from a broad perspective, to execute high-quality work through self-cultivation, and to fulfill a meaningful role in society through strong business performance and business expansion. As a result, we have established salary rules for fair payment of wages.

- Education system

- In order to encourage the voluntary growth of each and every employee, the Education Department fulfills a central role in constructing a unique education system. In particular, for their first 2 years after joining the Shimamura Group, R-employees (full-time employees) undergo practical training (OJT) at stores in order to acquire knowledge required of managers and to foster a high level of work-related awareness and motivation. They are also given an education by position (Off-JT) in order to systematically study other required knowledge and theory. Through this education, we aim to quickly develop talented human resources capable of independent action. In addition to education held for new employees, we have also prepared various education systems for continued employee growth over the long-term. Examples include specialized education by position and department, as well as support for self-improvement.

| New employee education (full-time employees) / | New employee education (part-time employees) |

| Education by position / | Education by department |

| Career training for female employees / | Correspondence education |

| Certification support system / | Seminars in the U.S. |

Low-cost operation

In order to operate retail chain stores efficiently at a high level, the Shimamura Group believes that it is essential to instill low-cost operations in every facet of our business.

The Shimamura Group has succeeded in reducing costs by thoroughly pursuing 4S, self-reliance, and standardization. We have also achieved low-cost operation as a rational mechanism.

- 4S

- A major principle of chain store operations is 3S, which is an acronym for "Standardization," "Simplification," and "Specialization." 3S streamlines the operation of multiple stores and leads to the achievement of low-cost operation

The Shimamura Group has added "Systematization" to 3S to create 4S. Systemization refers to assembling organizations based on rational ideas. We have continued to grow based on the concept of 4S. - In house development

-

- Distribution

-

For chain stores that supply products to stores all over Japan, the quality of the logistics system has a significant impact on operations and business performance. Although many logistics businesses outsource their own deliveries, the Shimamura Group began building our own logistics system from the time when we only operated 6 stores. Once our operations exceeded 30 stores, we established our own independently-operated transfer center. Since then, we have pursued mechanization, systemization, and growth in size. We have endeavored to streamline store operations and improve the convenience of our suppliers while always devising unique mechanisms.

- System

-

The information system that supports the core of a chain store is completely different depending on the number of stores being operated. From early on, the Shimamura Group emphasized system operation and created a comprehensive system suitable for 300 stores, 500 stores, 1,000 stores, and 2,000 stores according to the scale of our business.

Through in-house development of related systems, we can develop the optimal required system without waste, and we can also make fast improvements to the system. - Store development

-

While many retailers entrust location development to real estate agents, the Shimamura Group issues manuals which define standards for the appropriate location, scale, and conditions of stores. Staff at our Store Development Department directly handle all phases of location development, from trade area surveys to negotiations with landowners/owners, contracts, and licensing. The extremely low store closure rate demonstrates the superiority of our location system, which is a driving force for stable growth.

- Store construction/fixture development

-

In order to create stores and sales floors where customers can shop easily and employees can work comfortably, our specialized departments handle store construction and fixture development. In terms of store design, staff from our Construction Department give instructions to designers/builders and conduct on-site inspections based on our standard specifications, which give meticulous attention to every detail.

In terms of developing display fixtures and furnishings, in order to maximize the ease of purchasing by customers and the efficiency of store operations, staff from our Shop Dressing Department handle everything from design to instructions to fixture vendors and check of the actual products. Moreover, staff from our Shop Dressing Department use CAD (computer-aided design software) to design the sales floor layout of all stores, and we accumulate in-house know-how.

- Advertising

- We established a studio for product photography in the new head office that was relocated in January 2021. As a result, we are proceeding in-house with the provision of advertising products and products for our online store (photography of products, measuring and creation of manuscripts), which were previously done in an external photography studio. Moving forward, we will use our own studio to streamline and speed up our advertising operations.

- Manual

-

The Shimamura Group positions manuals as the basis of all operations. We pursue standardization and rationalization by conducting operations based on manuals in all departments. We have standardized the methods of our most outstanding veteran employees as a manual so that even new employees can perform their work above a certain level of skill at a high speed. Thorough standardization and rational operation based on these manuals are the basis of low-cost operation.

An improvement proposal system is an indispensable system to formulate manuals. The constant refinement of manuals is extremely important in order to achieve business optimization. In the Shimamura Group, more than 10,000 improvement proposals are submitted by all employees every year. We examine and test each proposal, and continuously update the results into new manuals every month. Operations are constantly improved to match current conditions, and low-cost operation is supported.

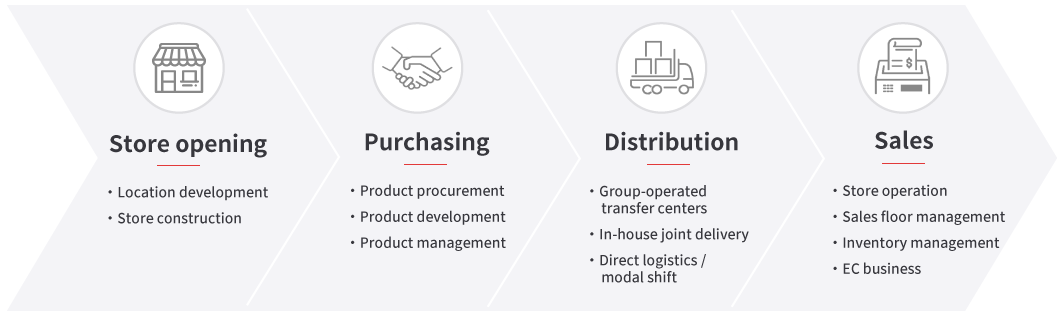

Shimamura's original mechanism

In order to provide quality products to customers at low prices, the Shimamura Group thoroughly implements highly-efficient and low-cost operations, which is the basis of our management. Therefore, we have built an original mechanism to realize low-cost operation in all processes of store openings, purchasing, distribution, and sales.

Store opening

Store opening

-

Location development

-

In the Shimamura business, we have been developing high-density stores through a dominant strategy (concentrated store openings in specific areas). Opening stores on suburban areas along the main road is based on ensuring a high market share on the premise of a small commercial area of approximately 15,000 households. The average annual purchase of clothing per household in Japan is about 100,000 yen. This means that the purchasing power of 15,000 households in a trade area is about 1.5 billion yen. The basis of one store is sales of about 300 million yen, which accounts for 20% of the purchasing power of the trade area. Such dominant strategies are also effective in improving the efficiency of deliveries from transfer centers to stores, and in raising awareness in the area of store located. Additionally, even for businesses other than the Shimamura business, we have set a standard for trade areas to match sales and customer base, and are engaging in store development based on dominant strategy.

-

Store construction

-

Standardization of stores is indispensable to achieve the dominant strategy throughout Japan at high speed and low cost. In order to achieve standardization, the Shimamura Group has proprietary construction standards for all structures such as buildings, parking lots, advertising towers, and exteriors. The staff from our Construction Department checks the entire process to make sure that the design and construction are compliant with those specifications. These standards enable the Group, designers and builders to carry out construction based on the same standards, and it is possible to quickly construct perfectly designed stores. Furthermore, we are constantly working to reduce construction costs by standardizing materials and reviewing our proprietary construction standards.

Purchasing

Purchasing

-

Product procurement

-

The Shimamura Group is a retail business that purchases products from suppliers (manufacturers, trading companies, etc.) and sells them. Although the apparel industry contains SPA "Speciality Store Retailer of Private Label Apparel" (manufacturing and retailing) corporations, pursuing the purchasing model enables us to concentrate on sales and improve our sales technology. In regards to product procurement, while building strong cooperation with about 600 suppliers based on long-term transactions, we make optimal use of the excellent design, product planning, and production control know-how of each supplier in order to improve our product development technology.

The buyer (Merchandise Department) is in charge of the product assortment and sales plan. The buyer purchases the most suitable items for the sales plan for each product category from the supplier. All business negotiations are conducted in a central buying format, which is carried out collectively by the buyers at the head office. By taking advantage of the economies of scale created by operating multiple stores, we are able to place large orders. This reduces purchasing costs and enables us to sell products at low prices. Suppliers make batch deliveries of products to our transfer centers. After delivery, we make complete purchase of all the procured products without any returns. This reduces costs incurred by the supplier, and builds an amicable transaction environment for both the supplier and the Shimamura Group. Furthermore, about 10% of all purchases are made by our Import Department, a specialized department that trades directly with outstanding overseas factories and procures products at low cost. This enables us to sell high-quality basic items at low prices.

-

Product development

-

The Shimamura Group's product lineup is based on a wide variety of products in small quantities. Our lineup is characterized by the excitement and fun of "treasure hunting;" that is, searching the many products for an item that suits your unique tastes. In particular, we focus on product development of various brands such as PB (Private Brands), which are developed in-house, and JB (Joint Development Brands), which are developed in cooperation with suppliers.

In the Shimamura business, we offer our PB "CLOSSHI" while maintaining a certain level of quality and price range for customers in a wide range of generations. CLOSSHI is centered on a basic design and focuses on comfort, usability, materials, and manufacturing.

For JB brands, the Shimamura Group clarifies the positioning of products based on "tastes" from such perspectives as elegant and casual aspects, and "generations" such as young people and married women. We then create a brand suitable for each area. Representative JB brands include HK WORKS LONDON, in the Shimamura business, and futafuta, in the Birthday business. Furthermore, for our JB brands, we are engaging in total sales of tops and bottoms on sales floors and to launch a brand worldview through online advertising, etc., thus working to increase recognition for brands among customers.

-

Product management

-

In order to provide products that enable customers to shop with peace of mind, the Shimamura Group formulates and operates in-house quality standards based on public standards (JIS, etc.). We ensure awareness for the standards by presenting them to suppliers when starting business transactions or when the standards are revised. This enables us to appropriately perform quality management and safety management.

In addition to quality inspections conducted by public inspection agencies, CLOSSHI and other PB products which are developed in-house are inspected by staff from the Merchandise Management Department. Furthermore, the Shimamura Group does not outsource on-site confirmation or improvement instructions for PB production factories to external organizations; instead, we conduct such activities by ourselves. We strive to prevent accidents (for example, unintended mixing of sewing needles or other dangerous substances) and solve problems that lead to defective products. At the same time, as part of initiatives to address sustainability issues, we also check the safety and working environment of workers engaged in production, and provide guidance for improvements.

Distribution

Distribution

-

Group-operated transfer centers

-

The Shimamura Group has 10 in-house transfer centers in Japan. Every day, we deliver products all over Japan. The basis of our logistics is speed. At our transfer centers, we are continuing to pursue labor saving and high-speed processing in order to deliver a large amount of packages in a short period of time. All packages delivered from suppliers are sorted by machine without manual handling by employees, thus achieving a high-speed process until transportation. This unique system enables us to operate the Higashi-Matsuyama Transfer Center, our largest transfer center, with only 4 full-time employees and about 30 M-employees. The high speed of our mechanized/automated logistics system and our in-house operation make it possible to deliver a package at a low cost which is approximately the same as mailing a single letter.

Additionally, the directly-managed online store that we opened in October 2020 uses a dedicated EC logistics center built on the premise of the Higashi-Matsuyama Transfer Center. We are also making improvements on an operational level in order to achieve unique low-cost EC; for example, we use our existing logistics network for store shipping to reduce logistics costs.

-

In-house joint delivery

-

Joint delivery is a mechanism for collecting packages from multiple companies and delivering them jointly. The Shimamura Group has 10 in-house transfer centers in Japan. The centers accept deliveries from approximately 600 suppliers. Suppliers enjoy reduced logistics costs through joint delivery of products to transfer centers, instead of having to make individual deliveries to each of more than 2,200 stores nationwide.

Products delivered from suppliers in the morning are sorted by store at transfer centers in the afternoon. Next, the sorted products are delivered to stores during the night when traffic is light, thus improving the efficiency of delivery by truck. At stores, the delivered products are inspected in the morning of the following day, so the products can be placed on the sales floors on the same day. In this way, we have built a joint delivery system that seeks overall optimization in all processes.

-

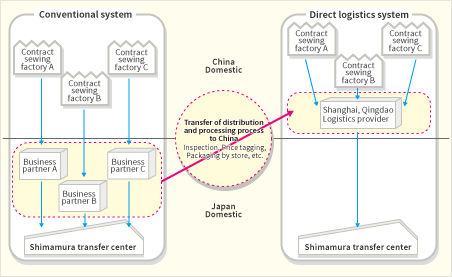

Direct logistics/modal shift

-

In direct logistics, logistics processing such as product sorting and price tagging, which was previously performed in Japan, is performed overseas at a relatively low cost. Next, the containers packed overseas are delivered directly to our transfer centers without passing through the distribution centers of suppliers in Japan. By delivering the products shipped from overseas production factories directly to our transfer centers, the time-consuming labor that occurs in the logistics channels in Japan can be eliminated, thus reducing distribution costs.

Additionally, for transportation between some transfer centers, we are promoting CO2 reduction by adopting modal shift (transitioning from truck transportation to marine shipping and railroads, which have less environmental impact) and improving logistics efficiency.

Fiscal Year 2020 2021 2022 2023 2024 Direct logistics ratio(%) 38.2 37.6 38.5 37.6 36.1 *Direct logistics ratio: Purchase cost of direct logistics ÷ Total purchase cost

Sales

Sales

-

Store operation

-

At our stores, the Shimamura Group executes thoroughly-standardized operations based on manuals. This makes it possible to operate stores by a small number of employees; specifically, 1 store manager and about 6 to 10 M-employees. The manuals provide easy-to-understand explanations for all the work necessary for store operation, from customer service and cash register operations to product arrangement, display, and cleaning procedures. The store manager operates the store by creating a daily work plan which enables M-employees to efficiently perform work according to sales forecasts, amount of product arrivals, etc.

Additionally, stores throughout Japan are organized as blocks for each area. About 5 to 6 stores are managed by 1 block manager. The block manager, while concurrently serving as the store manager of his/her own store, is responsible for improving sales for the entire block and providing guidance to store managers under him/her. By utilizing thorough standardization based on manuals and block management, we achieve high efficiency and high productivity at our stores.

-

Sales floor management

-

The Shop Dressing Department is responsible for the layout design of the sales floor and the development of display fixtures. The controller (Merchandise Department) is responsible for the display and production management of the sales floor after the products are delivered. This makes it possible to standardize and simplify sales floor management at all stores. Furthermore, the Sales Planning Department manages promotional materials used on the sales floor. It is responsible for controlling the sense of unity on the entire sales floor by centrally managing products and sales floors, sales promotion development schedules, and sales floor settings. The store manager manages the sales floor at each individual store, but the block manager in charge of a relevant area performs on-site confirmation every week and corrects the sales floor of each store in order to further enhance standardization at all stores.

-

Inventory management

-

The controller (Merchandise Department) is in charge of inventory management at all stores. The controller uses product data managed for each SKU ("Stock Keeping Unit;" the smallest unit of inventory management subdivided into colors, sizes, designs, etc.) to analyze product trends from various angles such as color, size, design, and region. Based on this analysis, the controller then moves each product from stores where the product does not sell well to stores where it sells better. For products that deviate from the initial plan and actual sales trends, the controller improves sales efficiency by implementing appropriate price markdowns. In this way, the controller controls the inventory of all stores at once, thus making it possible to sell the very last article of clothing at a low markdown rate.

-

EC business (directly-managed online store)

-

We opened our directly-managed online store in October 2020. The online store achieves reduced logistics costs by using the dedicated EC logistics center that was built next to the Higashi-Matsuyama Transfer Center, as well as the existing logistics network for store shipping. Through such measures, we are working to improve operational level in order to achieve low-cost EC that is unique to the Shimamura Group. In addition to increasing sales at our online store, our EC business seeks to increase sales at existing stores through mutual customer transfer between brick-and-mortar stores and EC. Currently, many customers who shop at our online store choose to pick up their order at a brick-and-mortar store. This is effective for sending customers from EC to brick-and-mortar stores.